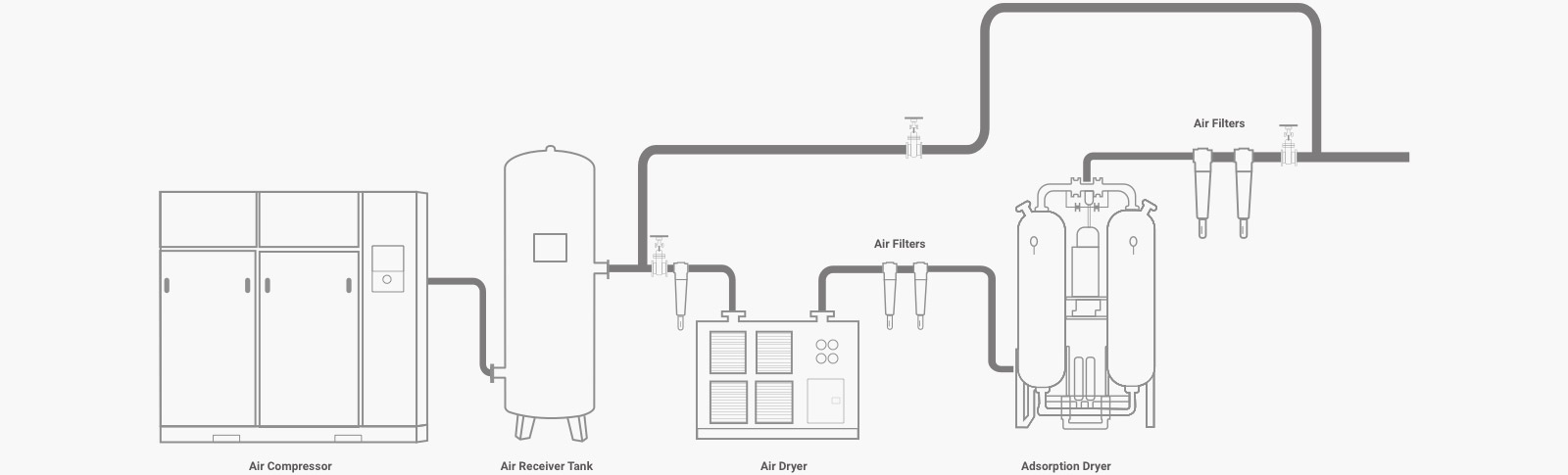

The primary function of an air compression system is to compress atmospheric air to a higher pressure for use in various industrial and mechanical applications.

DREAM Air Compressors is dedicated to providing comprehensive compressed air solutions and one-stop services to meet the demand for high-quality compressed air across various industries. DREAM offers a complete range of models, including piston, screw, scroll, oil-injected, oil-free, water-lubricated, fixed-speed, variable-speed, permanent magnet variable-speed belt drive, direct drive, integrated systems, single-stage and two-stage compression, stationary and mobile units, as well as low, medium (standard), and high-pressure options. Additionally, DREAM provides post-processing equipment, with a total of 17 product series and over 500 product options available for customers.

Oil-free air compressors are critical in industries where air purity is paramount. Unlike traditional air compressors, which rely on oil for lubrication, oil-free air compressors are engineered to deliver high-quality compressed air without the risk of oil contamination. This makes them a go-to choice for sensitive sectors like food and beverage, pharmaceuticals, electronics, and healthcare, where even the slightest contamination can compromise safety, quality, or regulatory compliance.

Compressed air generated by oil-free compressors meets stringent standards, including ISO 8573-1, which classifies air quality based on contaminants like particles, water, and oil. For the highest purity, Class 0 is the top classification, indicating that the air is virtually free of oil, ensuring no contamination during production. This level of purity is essential for applications where air comes into direct contact with products, such as food processing, bottling, and pharmaceutical manufacturing.

Choosing an oil-free air compressor is not only about eliminating oil contamination but also about improving overall air quality. Many facilities opt for rotary screw compressors, known for their efficiency and reliability, as part of their oil-free solutions. These compressors use advanced technology to provide high-performance compressed air without the need for traditional lubrication, making them ideal for 24/7 operations.

More >

Additionally, an oil-free air solution reduces the long-term costs and complexities associated with handling, disposing, and monitoring air compressor oil. By eliminating the need for oil, facilities can streamline maintenance, comply with environmental standards, and prevent accidental contamination, all while maintaining the highest standards of free air compressors.

This makes oil-free compressors an attractive solution for companies seeking to ensure air purity, enhance operational efficiency, and safeguard product integrity in industries where contamination is not an option. Whether in manufacturing, food and beverage production, or any sector that prioritizes air purity, oil-free compressors stand out as the cornerstone of reliable and efficient compressed air systems.

The dry oil-free air compressor is a reliable solution for industries requiring clean and uncontaminated compressed air. Designed to eliminate the need for lubrication during compression, these compressors ensure high air purity, making them indispensable for applications including food and beverage production, pharmaceuticals, electronics, and other sensitive environments.

Available in various types such as rotary screw and scroll compressors, oil-free air compressors are engineered to deliver efficiency and durability while adhering to the strictest standards of air quality. Many models meet Class 0 certification under ISO standards, guaranteeing air that is completely free from oil contamination. This makes them ideal for processes where air purity is non-negotiable.

With a wide range of capacities and configurations, oil-free compressors provide versatile solutions for industries of all sizes. Whether using a scroll compressor for smaller-scale operations or a rotary screw system for heavy-duty demands, businesses can rely on these compressors for consistent and high-quality performance.

The dry oil-free air compressor is a reliable solution for industries requiring clean and uncontaminated compressed air. Designed to eliminate the need for lubrication during compression, these compressors ensure high air purity, making them indispensable for applications including food and beverage production, pharmaceuticals, electronics, and other sensitive environments.

Available in various types such as rotary screw and scroll compressors, oil-free air compressors are engineered to deliver efficiency and durability while adhering to the strictest standards of air quality. Many models meet Class 0 certification under ISO standards, guaranteeing air that is completely free from oil contamination. This makes them ideal for processes where air purity is non-negotiable.

With a wide range of capacities and configurations, oil-free compressors provide versatile solutions for industries of all sizes. Whether using a scroll compressor for smaller-scale operations or a rotary screw system for heavy-duty demands, businesses can rely on these compressors for consistent and high-quality performance.

The dry oil-free air compressor is a reliable solution for industries requiring clean and uncontaminated compressed air. Designed to eliminate the need for lubrication during compression, these compressors ensure high air purity, making them indispensable for applications including food and beverage production, pharmaceuticals, electronics, and other sensitive environments.

Available in various types such as rotary screw and scroll compressors, oil-free air compressors are engineered to deliver efficiency and durability while adhering to the strictest standards of air quality. Many models meet Class 0 certification under ISO standards, guaranteeing air that is completely free from oil contamination. This makes them ideal for processes where air purity is non-negotiable.

With a wide range of capacities and configurations, oil-free compressors provide versatile solutions for industries of all sizes. Whether using a scroll compressor for smaller-scale operations or a rotary screw system for heavy-duty demands, businesses can rely on these compressors for consistent and high-quality performance.

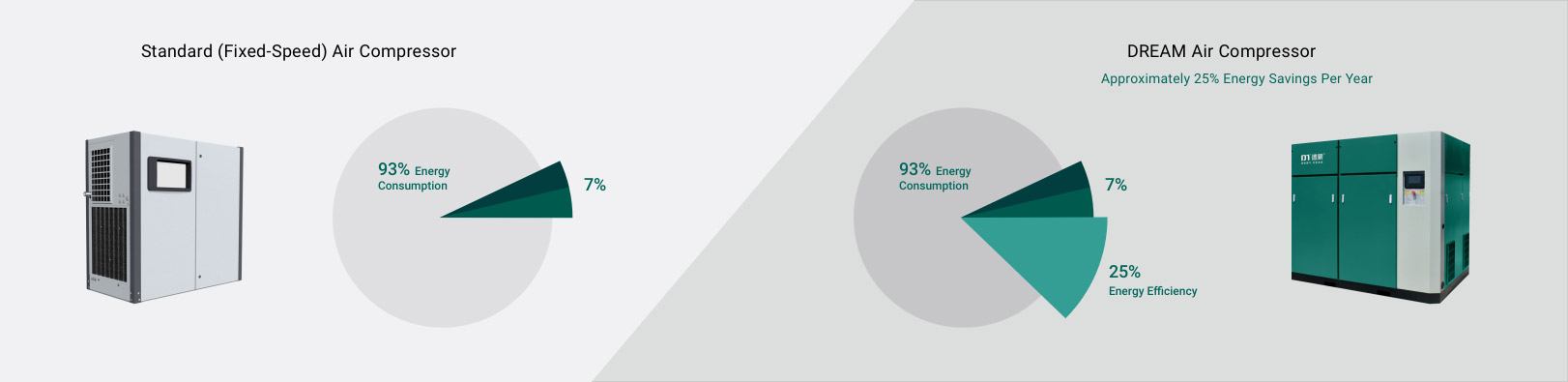

When purchasing an air compressor, the traditional cost (purchase cost + maintenance cost) accounts for only 7% of the total cost, while energy consumption makes up 93%. Our two-stage compression direct-drive and permanent magnet screw air compressors are 25-35% more energy-efficient than standard (fixed-speed) compressors.For example, with a 75 kW model

Introduction to Oil-Free Air Compressors.pdf

Download

Our oil-free air compressors, featuring a working pressure range of 2 to 40 bar, represent the core of our productportfolio, catering to a wide array of industries with their robust performance and reliability. Whether you require aow-pressure or high-pressure variant, our comprehensive range ensures that we have the perfect solution for youlspecific needs.There are the industries for Oil free air compressors :