If You use air compressor, you must know the name of Screw air end or screw element. What is it ? how it works ? through this article , you will learn all things about screw air end, its parts, its functions, its features.

Various names are used for the oil injected screw air ends. As the saying goes, a dear child has many names. Most commonly used names are air end, screw air end, screw block, block, oil lubricated air end, and rotary screw. Air end is not called “the heart of it all” for nothing. Where there are industrial operations, there are usually compressed air needs. Air ends are needed by compressor and compressed air system manufacturers. There are several different kinds of technologies to produce pressured air, for example reciprocating (=piston), membrane, vane, z-screw, liquid-ring, and turbo–compressors.

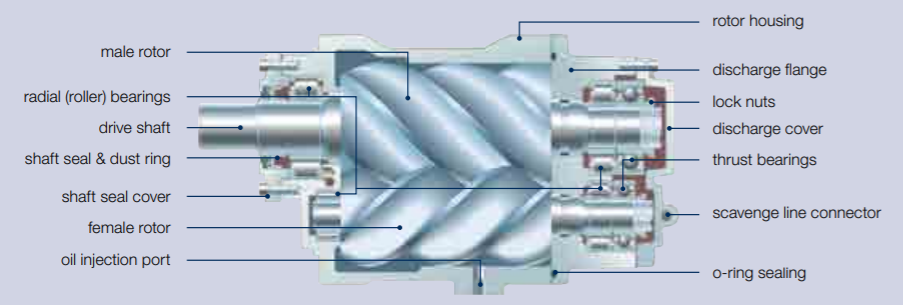

Air end is the part, where the actual compression takes place. Inside the air end are female and male rotors that rotate in opposite directions. They physically squeeze the air by an external force. Oil injected screw air end’s benefit is its very simple construction, where the air is compressed between two meshing rotors and against the frame with a thin oil film in between. The oil works as a coolant, sealant, and lubricant.

Screw air ends are designed to produce continuous, steady airflow. By this ultimate design criterion, screw air ends are great for applications where consistent airflow is a must, for example in industrial plants and operations. In addition to the continuous operation of the screw air ends, they are reliable and durable even in harsh conditions. For example, mining and construction rigs, as well as firefighting equipment manufacturers, choose screw air ends due to their reliability and durability. With oil injected screw, you can economically compress some 15 bar(g) max. and in two stage 45 bar(g) max. If higher pressures are required, multi-stage recips (pistons) are needed. For breathing air for divers and fire fighter tanks, 200 – 350 bar(g) can only be compressed by using multi-stage piston compressors, for example.

The air end of China's screw air compressor usually has the following three public version heads, Hanzhong Precision Machinery, Baosi Co., Ltd. and Changzhou Tongrun.

In terms of market share, Hanbell air end about 35%, Baosi estimates 40%, and Changzhou Tongrun and Jiuyi air end about 25%. In recent years, the proportion of Hanzhong mainframes has declined slightly, and Tongrun mainframes have increased rapidly in terms of permanent magnet frequency conversion mainframes. The Baosi remained basically unchanged.

In terms of price, the air end of Hanbell is higher than that of Baosi and Changzhou Tongrun. The prices of Baosi are slightly lower than those of Tongrun.

The design of the Hanbell air ends makes operation reliable and maintenance easy, ensuring minimal downtime.

With its cost-effective operation in a multitude of applications, we’re proud to claim that hanbell air end is one of the world’s most popular and reliable air end.

Our Dream Compressor has a strategic partnership with Hanbell, All our compressors are equipped with quality Hanbell air end. Our customers are very satisfied by their outstanding performance.