What is the Working Principles of Two-Stage Compressor?

The operating principle of a two-stage compressor relies on a meticulously planned sequence of steps, ensuring efficient, energy-saving air compression with consistent quality. Below is a comprehensive explanation of its working mechanism:

Two-Stage Compression Screw Air Compressor Workflow:

1.Air Filtration & First-Stage Compression

Air initially passes through an air filter, entering the compressor for initial compression.

During this phase, a minute amount of lubricant oil mixes with the air, simultaneously compressing it to the intermediate pressure.

2.Cooling:

The compressed gas then flows into a cooling channel, encountering a generous amount of oil mist.

This interaction significantly reduces the gas temperature, enhancing compression efficiency and mitigating heat-related issues.

3.Secondary Compression:

Following cooling, the gas progresses to the second-stage rotor for further compression.

Here, it is compressed to the final exhaust pressure, marking the completion of the secondary compression phase.

4.Exhaust:

Upon two-stage compression, the gas exits the compressor via the exhaust flange, successfully concluding the entire compression process.

What is the Benefits of Two-Stage Compressor?

Benefits of Two-Stage Compression:

Efficiency Boost: By distributing the compression load across two stages, the overall process becomes more efficient.

Energy Savings: Reduced heat generation and improved thermal management lead to substantial energy savings.

Extended Lifespan: Lower operating temperatures minimize wear and tear on components, extending the compressor's lifespan.

Consistent Output: Two-stage compression ensures consistent air quality and pressure, suitable for a wide range of applications.

5. What is the Principles Behind Two-Stage Compression Screw Compressors?

This system divides the compression process into two distinct phases, leveraging a casing that houses two-stage rotors. Each rotor stage operates at high-efficiency speeds, resulting in a compression process that is both efficient and energy-conservative. This design philosophy not only enhances compression efficiency but also contributes to reduced equipment operating costs.

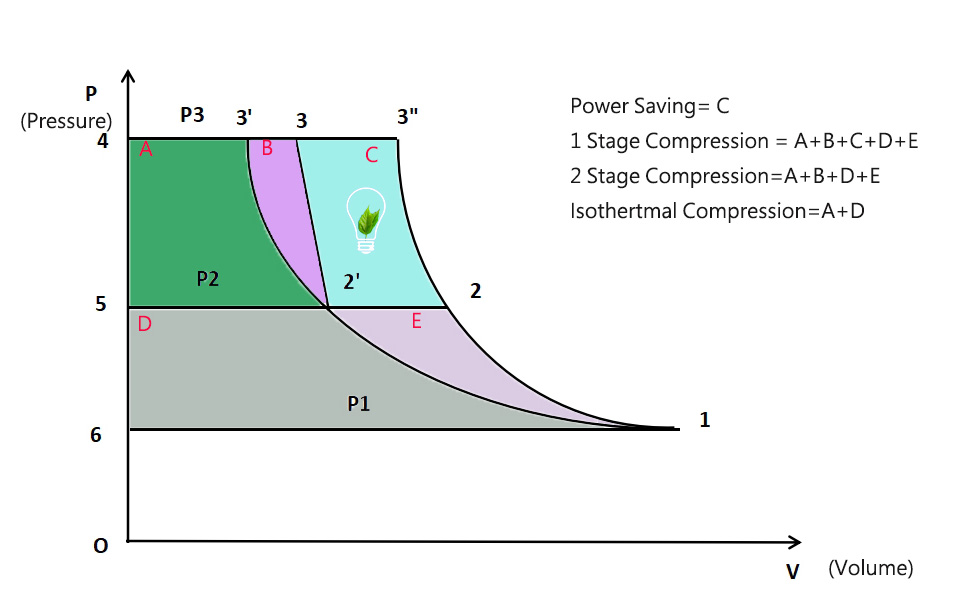

In order to understand of the air compressor compression process with P-V diagram, as shown in Figure F-0827, 613'46 for the isothermal compression process. If a single-stage compression, the work consumed is equivalent to the area 613 “46; when using two-stage compression, the work consumed is equivalent to the area 61256 and the area 52345 and. The work saved is equivalent to the area 223"32, but compared with the isothermal compression, still consume more area 1221 plus the area of 2'33'2' of work.

The benefits of employing a two-stage compression process in oil-injected screw air compressors, particularly in terms of energy efficiency, are pronounced becase the factors as below.

Firstly, the implementation of two-stage compression extends the compression cycle, ensuring a thorough blend of oil and gas. This, in turn, brings the compression process closer to isotherm compression, with each stage featuring a reduced pressure ratio, minimizing internal leakage and enhancing volumetric efficiency.

Manufacturers of two-stage compression hosts and systems show distinct traits, such as the using of multi-point oil injection to achieve a more uniform oil-gas mixture and specialized stage-to-stage designs incorporating fog spray curtains to mitigate secondary suction temperature, ultimately enhancing efficiency.

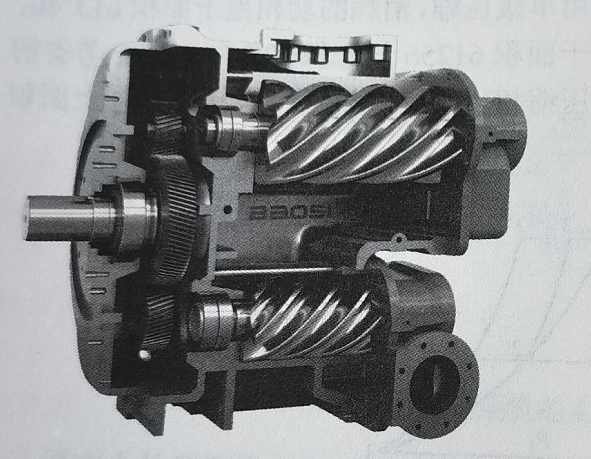

As depicted in Figure 1, the BAOSI air end, two-stage compression screw host showcases a two-pair rotor layout in an upper-lower configuration.

Now, let's introduce the key features of this Air End:

It boasts upper and lower independent compression units integrated into a compact design, maximizing structural efficiency.

Employing an equal internal pressure ratio design and incorporating forced atomized oil cooling between stages, it closely mimics isotherm compression, enhancing energy savings.

The exhaust end features a double-tapered bearing design in a face-to-face configuration, utilizing premium bearings from brands like SKF, FAGNTN, and NSK, with a projected bearing lifespan exceeding 60,000 hours.

Adhering to the design principle of large rotors and low rotational speeds, the main shaft rotates at 1480 r/min, ensuring low noise and vibration levels.

Each compression stage operates at a low compression ratio, further contributing to its overall efficiency.

By lowering the compression ratio at each stage, we minimize internal leakage, resulting in an 8% to 15% boost in volumetric efficiency.

The ability to fine-tune the rotor of each stage allows for achieving an optimal linear speed range of 25 to 35 m/s, thereby maximizing compression transfer efficiency.

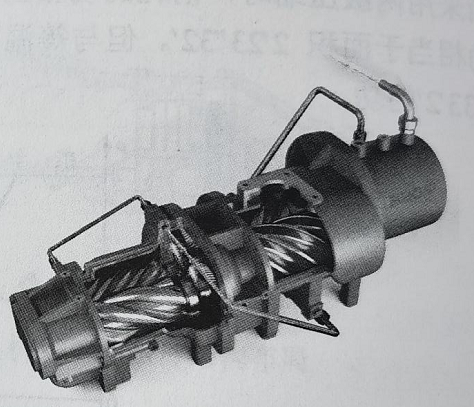

Figure below illustrates the horizontal configuration of the BAOSI air end two-stage screw compressor mainframe.

The BAOSI YHE series of horizontal, two-stage screw air compressors incorporate the latest BAOSI 4-6 tooth profile, which boasts the following features:

① A sleek, integrated design that combines machine stop functionality with oil-cooled direct motor coupling for a more compact structure. The reduced leakage triangle, balanced contact line length, and closely matched tooth tip linear velocities streamline manufacturing processes. Additionally, optimized wall thicknesses and a split structure simplify both fabrication and assembly workflows.

② An optimized horizontal layout that eliminates the need for spindles, spindle gears, and bearings by directly connecting to the drive shaft, leading to cost savings.

⑤ A refined oil circuit design ensures precise distribution of oil injection volumes between stages, enhancing energy efficiency and promoting sustainability.

DREAM air compressor one leading brand in Air Compressor solution provider and Manufacture with 14 years experience. We provide all kinds of oil injected two stages compressors.