1.1 Functions of the compressor

Increase the pressure of the gas and transport the gas

1.2 How to realize gas compression

Regarding the pressure of gas, in physics, there is a clear definition and description:

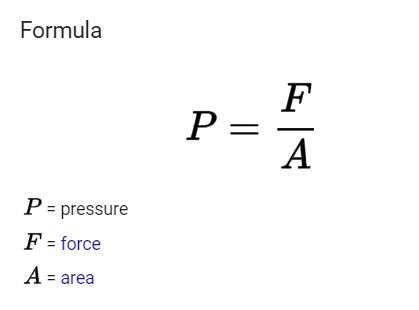

Pressure is the amount of force applied perpendicular to the surface of an object per unit area. The symbol for it is "p" or P.

Analytical results from the theory of molecular motion of gases show that the pressure is proportional to the product of the number of molecules per unit volume (density) and the average kinetic energy of the molecules. This is expressed by the formula.

n-number of molecules per unit volume (density).

mv2/2-a molecule's average kinetic energy.

Obviously, if the density of the gas is increased or the kinetic energy is increased, both can increase the pressure of the gas.

Formula

P=(F/A)∞ n*(mv2/2)

1.3 Two ways of gas compression by a compressor

The mass of the gas in the closed volume is m and the volume is V , then the density p is.

P=m/V

A certain mass of gas is enclosed in a certain volume, such as reducing the volume of the enclosed volume V, the density of the gas p increases, the pressure of the gas increases to realize the compression of the gas.

We call this compressor, which realizes the increase of gas pressure by reducing the closed volume, a Positive Displacement Compressor .

By increasing the speed (kinetic energy) of the gas, the kinetic energy of the gas is converted into the internal energy and pressure energy of the gas, thus realizing the increase of the pressure of the gas and achieving the purpose of compressing the gas. Compressors applying this principle are called Dynamic Compressors.

1.2Compressor applications

As a general overview, compressors are used in the following four main applications

*Divided only from the field of application, and not categorized in the strict sense.

(1) Compressed air as a power source.

(2) For chemical processes.

(3) Compressed gas for refrigeration and gas separation.

(4) Gas transportation.

1.2.1 Compressed air as power

Compressed air to drive a variety of wind-driven machinery, wind-driven tools, such as pneumatic pick, pneumatic drill, pneumatic wrenches, sandblasting, painting, etc., for the control of instrumentation and automation devices, material handling and other air sources. In addition, in the field of national defense, scientific research, such as the launch of certain weapons, submarine operation, shipwrecks salvage, undersea oil exploration, all need different pressure of compressed air.

Compressed air as a power and control air source is the main purpose of the air compressor. As an air compressor, its main characteristics are: inlet pressure is generally atmospheric pressure, exhaust pressure are different according to the application of different requirements.

The following are some typical application of air compressors.

(1)pneumatic pick, nail guns, pneumatic wrenches, etc. The advantages are impact resistance, adjustable working conditions, and large driving force.

(2) Braking, door and window opening and closing on transportation vehicles, engine pressurization, etc. The advantages are easy integration,

High reliability.

(3) Textile machines are used for blowing and feeding weft yarns. Fermentation in the food and medicine, slurry mixing, pneumatic conveying, etc.

(4)automated production lines use a large number of cylinders as moving parts need air compressors to provide air source compressed air has easy to store, easy to control, good mobility, safety, environmental protection characteristics. Therefore, compressed air is also considered to be the second power source after electricity.

1.2.2 Compressors for chemical processes

In the chemical industry, increasing gas pressure is conducive to chemical reactions, improving reaction speed and productivity, and reducing the size of the equipment and the cost of the project. For example, fertilizer production in the ammonia process to make hydrogen and nitrogen in the 15 ~ 100MPa pressure reaction, so the ammonia process is the core equipment of nitrogen compressor, hydrogen compressor, nitrogen-hydrogen cycle compressor; urea production needs to be 21MPa under the carbon dioxide and ammonia chemical reaction; petroleum hydro-refining needs 7 ~ 32MPa pressure; plastics, synthetic fibers, plastics, synthetic fibers, elastomers and other chemical products is based on polyethylene, and polyethylene is

Polymerization of polyethylene from ethylene under a working pressure of up to 280MPa.

In these processes, the compressor is the key equipment similar to the human heart. It can be said that without compressors, there would be no petrochemicals, and without petrochemicals, the vast majority of modern society's products made from non-natural materials would cease to exist.

1.2.3 Compressed gas for refrigeration and gas separation

Used in artificial refrigeration (freezing, refrigeration and air conditioning), such as ammonia and gas Leon compressor, its pressure is usually 0.8 ~ 1.4MPa, this type of compressor is called refrigeration compressor (industrial refrigeration field is often commonly known as “ice machine”).

We know that air can be liquefied after compression and cooling. Liquefied air can be separated in the separation device according to its different classification temperature will be separated from the components, you can get pure, pure, and pure xenon, neon, argon, helium and other rare gases. Air separation (air separation) equipment are based on compressed gas to gas purification.

The rapid development of China's petrochemical industry, the separation of its raw gas - oil cracking gas, is first compressed, and then using different cooling temperatures, the components are separated.

1.2.4 Compressor for gas transportation

The main gas transportation methods are pipeline transportation and bottle transportation.

When the gas volume is large and continuously transported by pipeline transportation, the compressor is used to increase the pressure of the gas to overcome the resistance of the pipeline in the flow process, and to make the smaller pipe diameter to transport as much gas as possible.

The pressure for gas pipelines is between 0.3 and 3 MPa. For natural gas pipelines, the pressure ranges from 1 to 10 MPa. China's West-East Gas Pipeline is the world's longest natural gas pipeline. China's West-East Gas Pipeline is the longest natural gas pipeline in the world. It has many pressurization stations along its path. The main equipment in these stations is the natural gas pipeline compressor.

Liquefied gas can also be taken to be transported by land and sea. Liquefied natural gas takes up much less space than gaseous natural gas.

It is about 1/625 of the original volume. This makes it easier to store and transport in large amounts. Here, the natural gas compressor is the core equipment.

The compressor used for gas bottling depends on the nature of the gas. General oxygen cylinder pressure of 15MPa, acetylene gas nature is not stable, bottling pressure of 1 ~ 2MPa, and by acetone to be adsorbed.

Some of the critical temperature of the gas can be easily liquefied, can be compressed first, after cooling to make it liquefied and then bottled, such as chlorine bottling pressure of 1 ~ 1.5MPa, carbon dioxide bottling pressure of 5 ~ 6MPa. Liquefied petroleum gas is now commonly used. It is bottled at a pressure of 0.5 to 1.5 MPa. Hydrogen cylinders for fuel trolley cars are filled at a pressure of 35 to 70 MPa.

Natural gas vehicles are refueled at sub-stations. The gas transfer tankers transport gas at a pressure of 20 MPa.

The compressor plays an important role in the national economy. This includes ethylene machines, natural gas pipeline compressors, and wind tunnel compressors. Compressors not only on industrial production, but also on our daily life, national defense construction and other significant impact.